Background information

What do the Olympics have to do with Olympia, the German manufacturer of typewriters?

by Martin Jungfer

I’m tired. So very tired. After feeding my brain with seven hours of mattress-related content, thoughts of sleep are closing in. Here’s my behind-the-scenes report into the Bico mattress factory in the tiny Swiss village of Schänis.

What can I say about the mattress on my bed? It’s square, it’s white and I lie on it for eight hours a day. The mattress does its job pretty well – it’s not one of those cheap varieties. After a consultation in a specialist store two years ago, my wife and I shelled out a four-figure sum for mattresses and bed slats. Per person.

At the time, I had an inkling I’d fallen prey to clever mattress marketing. After a bit of back and forth, I recently got the chance to meet Jens Fischer, Bico’s Marketing Director. My detective instinct was piqued – the Swiss manufacturer is the very company that made my luxury mattress.

Für ä tüüfä gsundä Schlaaf (English: For a good night’s sleep).

One friendly e-mail exchange later, the time had come. Having received the green light to see how the mattresses are made, I headed to Schänis with photographer Chris Walker. 3,800 people live in the town nestled between Zurich-Obersee and Lake Walen. It’s the home of Bico, a brand belonging to the Swedish-based Hilding Anders Group.

Formerly known as Birchler und Co. and based in Reichenburg in the canton of Schwyz, the «Bi» in Birchler was merged with «Co» to create the name Bico AG in 1961. The following year, the company conquered the Swiss bed market with the Isabelle – the first ever foam mattress without steel springs. It became a bestseller: the Volkswagen Beetle of the Swiss mattress market. It’s still produced today – in four versions, various sizes and differing degrees of firmness. Isabelle is now a separate Bico product line, even including comforters and bed bases (download in German).

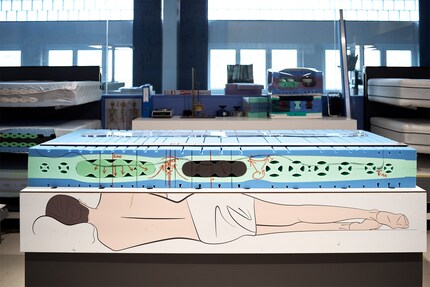

Every model can be traced back to the mattress factory at the company’s headquarters in Schänis. The mattresses have pretty-sounding names: Body Fine, Body Luxe, Clima Pro and Vita Feel. They certainly sound more modern than the blue and grey, 70s factory looks from the outside. Bico’s Innovation Manager Rocco Cristofaro joins us on our tour alongside the Marketing Director.

The factory floor could easily hold a football pitch. It looks like an oversized sewing workshop. And it kind of is, as fairly large swathes of fabric are sewn here, usually measuring at least 90 by 200 centimetres. Half of all mattresses Bico sells are made in this dimension.

But let’s start from the beginning. More specifically, the inside of the mattress. To see this, we need to drive from Schänis to Wolfhausen, a village in the municipality of Bubikon, first. This is where Foampartner AG is based.

You don’t normally see what’s under the fabric of a mattress. Sometimes, the salespeople in specialist bed shops will show you a cut-open cube containing springs and brightly coloured foam. The foam in the core of a mattress plays a decisive role in whether you wake up in the morning feeling rested or stiff. Bico’s foam – the stuff dreams are made of – isn’t produced by the company itself. Instead, Bico’s teamed up with Foampartner AG. As Rocco Cristofaro puts it, this is who «bakes the cake». For decades now, the village has been home to Foampartner’s 120-metre-long plant. Its machines churn out foams based on polyurethane (PU), which are used in Bico mattresses as well as other products. As Product Development Manager Felix Posavec explains, they also produce all sorts of «technical foams». These include foams for car seats, acoustics in recording studios and sponges.

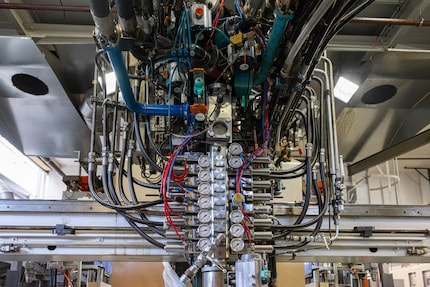

Right now, a black foam cake is being produced. It’s a beast, measuring over 50 metres in length. It all starts with the «dough», a liquid resulting from a mix of polyols and isocyanates. As soon as water is added, the chemical reaction begins. The liquid runs onto a baking paper-like surface, rising like yeast in a matter of seconds. By the time it’s travelled almost eight metres, the black liquid has transformed into a solid, 80-centimetre-high block. Another layer of «baking paper», held down by a piece of metal, goes on top of the block to keep the surface as flat as possible.

These cakes reach 30 metres in length before a saw slices them up. The blocks are then taken to the cold storage area – a dark warehouse with dozens of storage spaces. Fresh off the production line, the inside of a foam block can reach a temperature of 180 degrees Celsius, taking up to three days to cool down.

All kinds of additives in the liquid base material are used to determine the final properties of the PU foam. Felix explains that up to 20 components can be added here in Wolfhausen – a much wider range of options than offered by competing factories overseas. At these plants, Felix adds, perhaps 5-7 additives would be used. «That’s fine for standard foam produced in bulk,» Felix says. Small quantities of speciality foams, such as the kind required by Bico, however, are Foampartner AG’s strong suit.

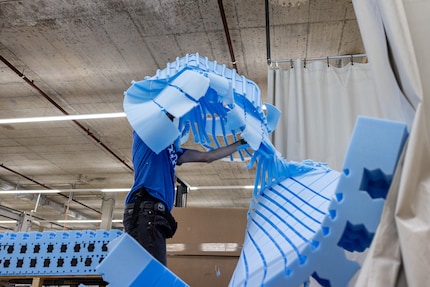

In the warehouse, I see what counts as a «small quantity» in Felix’s world. Dozens of brightly coloured foam blocks are stacked here like oversized bricks. I watch a forklift truck piling up some sky-blue varieties. «Those are for our Clima Pro mattress,» says Rocco. «They’re particularly airy, yet stable.» The foams aren’t just coloured for marketing purposes. The lighter the foam, the softer it is. They come in almost any colour of the rainbow. The guys in the warehouse know exactly what each colour means, which foam is for mattresses and which is for insulation or improving acoustics.

Once a foam block has settled sufficiently, it’s cut into slices. At this point in the process, we’re still in Wolfhausen and haven’t yet moved on to Bico in Schänis. The faces of the blocks are evened out to create a perfect cuboid. This is then cut into layers of a suitable height. After that, precision machines with very sharp knives mill 3D contours for the mattress cores – cavities for different foams or springs. Finally, the components are pieced together to form the finished core; a process mostly done by hand. These so-called pre-products are then transported to Bico in Schänis.

We follow the pre-products on their journey back to Schänis, where the mattress cores are given their covers. As Rocco explains, this is key:

When you lie on a mattress, you can’t see the foam in the core. You can’t touch it. What you feel against your skin is the mattress cover.

At this point, handcraft is crucial. Experienced seamstresses work at sewing machines to make the cover, using various fabrics. «Every fabric behaves slightly differently, and machines can’t handle that. It takes a lot of intuition,» explains Markus Läser, Head of Production at Bico.

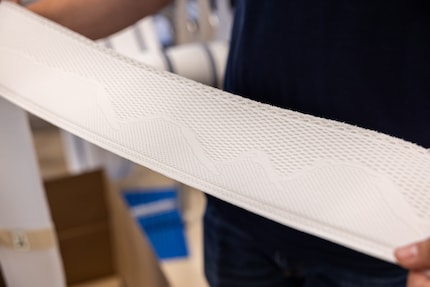

Bico manufactures mattresses to order. Each core has to be covered with a kind of thin stocking first before being given its cover. Two days later, it’s ready to be shipped. On this tight a schedule, The Mammoth has to work quickly. That’s the name of the fine-needle machine that uses 100 needles to sew the mattress cover. The material? Sheep’s wool fleece and another panel of fabric, the top surface. A computer determines which quilting pattern the seams should create, which varies depending on the mattress.

Many of the covers are decorated with a stylised Swiss cross, serving as both a trademark and a sign of Bico’s commitment to manufacturing in Switzerland. Production Manager Markus is convinced that «sustainability begins with regionality», using sheep’s wool as an example to illustrate what he means. All the wool the company uses comes from Switzerland. Twenty-six sheep farms across the country supply their product to Bico. Wool buyers used to be thin on the ground, causing a lot of the material to be thrown away. But Bico has created a new market for it. The Mammoth processes up to 850 metres of fabric in one day, creating over 450 mattresses.

Anything the machine ejects goes on a large table decked with sewing machines. This is where the seamstresses work, using a foot pedal to control the speed of the needles moving up and down. They push the heavy fabric panels forward using the free arms on the left and right, attaching zippers and borders. Markus is hugely appreciative of the seamstresses:

They’re essentially like helicopter pilots.

Their work requires a high level of concentration and coordination. Men don’t seem to be up to the task – the sewing tables are safe in women’s hands.

In Switzerland, handcraft comes at a price. Despite this, it’s still done at Bico, as Markus and his team are always coming up with ideas for improvements. The tricky stage of sewing a mattress cover – the corners – was made easier when the team started using a sewing machine that cuts the thread immediately after the seam. When you’re making hundreds of covers a day, every second saved counts.

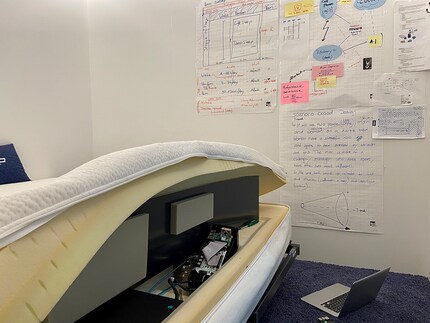

If a manufacturer opts to work out of Switzerland, they’ll have slim chances on the market with run-of-the-mill products. The brains behind Bico’s lead over the competition are Rocco Cristofaro and his development team. Opening the door to the factory floor takes you into Rocco’s kingdom. The walls of the office wing, which has an adjoining test laboratory, are plastered with data from a laborious market research initiative Bico conducted two years ago. According to the results, four things are important to customers on the hunt for a mattress: they don’t want to freeze or sweat, they don’t want to wake up in pain, the mattress should last a long time and it should be perfectly hygienic.

The last point, Rocco explains, is why all Bico covers are washable at 60 degrees – a feature that’s continuously put to the test. Instead of an industrial washing machine, the Schänis plant has an Adora model from V-Zug, Switzerland’s favourite washer.

When it comes to the lifespan of a mattress, today’s rule of thumb is that you should replace it every 8-10 years. Although a mattress’s foam core and springs could go on providing support for much longer, Rocco says there’s still good reason to swap it out. After many years of daily use, mattresses accumulate some fairly unpleasant residue – roughly two kilogrammes of droppings from mites and other tiny creatures, to be precise. How do they know that? By comparing the weight of new mattresses with ones that have been used for a long time.

Before a new mattress hits the market, it’s subjected to Bico’s own test procedures. Lying on a new mattress in an environmental test chamber, there’s a «sweater body», a metal body that emits heat and moisture in a similar way to a human one. The chamber measures how quickly and effectively moisture escapes from the mattress once the sweater body has finished its simulated sleep.

Elsewhere, a computer records and assesses the pressure distribution of a body on new foams. How well can the top layer distribute a person’s weight? How much does the area beneath the sleeper’s shoulders yield? Is there lumbar support too? These are the questions Rocco and his team come here to answer.

The 42-year-old seems to find inspiration for new ideas everywhere. These days, he’s pondering the question of whether the cushioning system of a popular Swiss sneaker could also be used in mattresses. Another invention is already in the pipeline; a bed base that provides better support in the shoulder area via slats in the same spot being rotated 90 degrees. «It was a truly interdisciplinary project,» says Rocco, praising the collaboration with the production team.

Then, Rocco shows me his «hobby». This is where he transforms into Gyro Gearloose. I spot some Raspberry boards next to a double bed mattress with thin cables running into it. Numerous small electric motors measure and react to pressure coming from the body above. As people move while they sleep, they always need support and relief placed as precisely as possible. Potentially, this could be controlled mechanically. «It’s still a long way off, though,» Rocco laughs.

A more pressing question is what kind of toll mattress production takes on the environment. Obtaining polyol to make the foam takes 60 litres of crude oil alone. Even if other raw materials are refined from that, it’s still produces a large amount of CO₂. Rocco’s kingdom is filled with mattress cores, some of which are made from foam scraps. There are some fledgling initiatives in the industry based on how mattresses can be recycled at the end of their lives. Although Bico played a key role in initiating them, Rocco’s still self-critical:

It’s clear we still have a way to go.

Foams with exquisite ingredients. Seamstresses who operate their sewing machines with the focus and precision of helicopter pilots. Now I get why mattresses produced in the Bico factory cost more than others. Even so, I still have questions. Rocco’s been in the business long enough to know the tricks to successfully selling a mattress.

«We obviously pay attention to the first impression our mattresses make,» he explains. The outer fabric of the cover plays an important part in this. When a customer first sits down on a mattress in a store, they run their hands over the fabric and the edge. Bico mattresses catch the eye with their Swiss crosses sewn into the quilting pattern. The inside of the mattress only comes into play when the customer tries it out. Ideally, this is done when they’re wearing comfortable clothing and have plenty of time. During the test, they can feel where their body sinks into the mattress and where it’s supported.

Some manufacturers advertise seven- or even nine-zone mattresses. However, as Rocco explains to me, every mattress essentially has three zones – one for the shoulders, one for the lumbar area and one for the pelvis. Anyone touting seven-zone varieties is simply doubling these three zones and one more for the head. For a mattress to be right, it needs to strike a balance between yielding (at the shoulders and pelvis) and supporting (at the lumbar area). This requires using different foams or springs in the right places. There are also additional layers for pressure relief, weight distribution and ventilation.

Cheap mattresses often only consist of two or a maximum of three different standard foams. As a result, they can only meet these requirements to a certain extent, says Rocco. Naturally, these mattresses are cheaper. At the same time, manufacturers who use a small number of standard products can also reduce their costs. If I had «standard» body, I could’ve saved some cash by buying a «standard» mattress.

After my day in the mattress factory, I’m pretty sure I won’t ever order a mattress online without trying it out first. When it’s time to make my next purchase, I’ll talk shop with the salesperson about cold foams and lumbar support until I’m sure I’m lying on a mattress dreams are made of.

Header image: Christian Walker

Journalist since 1997. Stopovers in Franconia (or the Franken region), Lake Constance, Obwalden, Nidwalden and Zurich. Father since 2014. Expert in editorial organisation and motivation. Focus on sustainability, home office tools, beautiful things for the home, creative toys and sports equipment.

Interesting facts about products, behind-the-scenes looks at manufacturers and deep-dives on interesting people.

Show all